Stihl bad coil symptoms include difficulty starting or running the engine. Replacing the faulty coil is the solution to the problem.

A stihl chainsaw is no doubt a powerful piece of equipment. However, it is not immune to faults and breakdowns. The ignition coil is a vital component of the chainsaw’s ignition system. Without it, the chainsaw cannot start or run.

When the coil gets damaged or faulty, it disrupts the ignition system, leading to a host of problems. As a result, it is essential to know the stihl bad coil symptoms and get the coil changed promptly to avoid any further damage and ensure optimal performance. This article will take a closer look at the common stihl bad coil symptoms to help you detect them early.

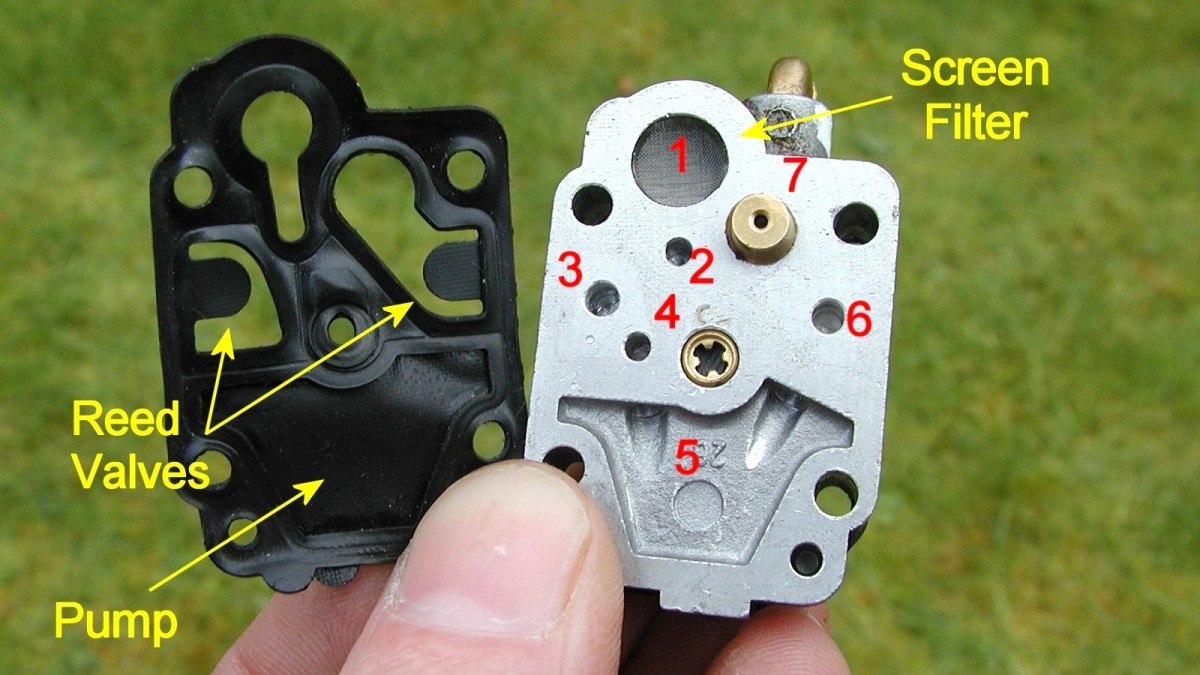

Credit: www.youtube.com

Understanding The Role Of A Coil In A Stihl Engine

Stihl Bad Coil Symptoms

Have you ever experienced a sudden drop in performance in your stihl engine, leaving you frustrated and unsure about what went wrong? Well, in most cases, it’s a faulty coil that’s the culprit. The coil plays a major role in the functioning of the engine, and if it goes bad, it can affect the overall performance.

We will discuss the role of a coil in a stihl engine, the symptoms of a bad coil, and how it affects engine performance.

Definition Of A Coil In Stihl Engines

Before delving into the details, let’s first define what a coil is. The coil is an essential component of a stihl engine’s ignition system. It converts the battery’s low voltage into the high voltage necessary to create a spark in the spark plug.

The spark generated ignites the fuel-air mixture in the engine cylinder, triggering the engine’s combustion process.

Understanding The Role Of A Coil In Engine Performance

Now that we know what a coil is let’s understand its role in the engine’s performance. The coil’s job is to ensure a consistent and reliable spark at the right time, allowing for efficient combustion of the fuel-air mixture. This, in turn, leads to better engine performance, improved fuel efficiency, and reduced emissions.

A properly functioning coil is crucial in ensuring your stihl engine runs smoothly and efficiently.

How A Bad Coil Affects Stihl Engine Performance

A bad coil can have a significant impact on your stihl engine’s performance and can lead to a range of problems. Here are some of the common symptoms of a bad coil:

- Failure to start or difficulty starting the engine

- Engine misfiring

- Stalling or sudden engine cut-out

- Uneven idling

- Decreased power or acceleration

These symptoms indicate that the engine isn’t receiving appropriate spark, or the spark is not happening at the right time. A bad coil often leads to a weak and inconsistent spark, which leads to incomplete combustion and ultimately affects the engine performance.

The coil plays a critical role in the efficient functioning of a stihl engine. If you experience any of the symptoms mentioned above, it might be time to replace your coil. Remember always to use genuine stihl parts and seek help from a professional mechanic if you experience any problems.

Top 5 Symptoms Of A Bad Coil In A Stihl Engine

Stihl Bad Coil Symptoms

If you own a stihl engine, you have probably experienced some problems with it. One of the most common issues with these engines is a bad coil. This component is responsible for generating the spark that ignites the fuel in the engine.

When it fails, you will experience a range of symptoms that indicate a bad coil. In this post, we will discuss the top 5 symptoms of a bad coil in a stihl engine.

Difficulty Starting The Engine

If you are having problems starting your stihl engine, it may be due to a bad coil. When the coil fails, it can no longer generate the spark that ignites the fuel in the engine. As a result, the engine may crank, but it won’t start.

You may also notice that the engine starts but then quickly stalls.

- The engine cranks, but it won’t start.

- The engine starts but then quickly stalls.

Engine Misfires Or Stalls

If your stihl engine is misfiring or stalling, it could be due to a bad coil. When the coil fails, it can no longer generate a consistent spark. As a result, the engine may run rough, misfire, or stall. This can happen at any time, but it’s more likely to occur at high speeds or under heavy load.

- The engine runs rough.

- The engine misfires or stalls.

Decreased Power Output

If you notice a decrease in power output from your stihl engine, it could be due to a bad coil. When the coil fails, it can no longer generate a strong spark. This can result in a decrease in power output, which can make it difficult to operate your equipment efficiently.

- The engine has a decrease in power output.

Decreased Fuel Efficiency

When the coil fails, it can cause the engine to run rich, which means it consumes more fuel than necessary. This can cause a decrease in fuel efficiency, which can increase your operating costs.

- The engine consumes more fuel than necessary.

Engine Overheating

If your stihl engine is overheating, it could be due to a bad coil. When the coil fails, it can cause the engine to misfire, which can generate excess heat. This can cause the engine to overheat, which can damage other components of the engine.

- The engine misfires, generating excess heat and causing the engine to overheat.

A bad coil in your stihl engine can cause a range of symptoms, from difficulty starting the engine to decreased fuel efficiency and engine overheating. If you experience any of these symptoms, it’s essential to have your engine serviced by a qualified technician.

Don’t wait until the problem becomes severe and causes significant damage to your equipment.

Common Causes Of A Bad Coil In A Stihl Engine

If you own a stihl engine, you may have experienced problems with the coil. A coil is the device responsible for generating the electrical spark that ignites the engine. When the coil fails, it can cause your engine to malfunction or stop working altogether.

Here are some common causes of a bad coil in a stihl engine:

Age And Wear And Tear

Over time, coils can wear out due to regular use, especially if they are not well-maintained. If your engine has been in use for a while, it’s important to keep an eye on the coil and replace it if it begins to show signs of wear.

Some symptoms of coil wear include difficulty starting the engine, rough idling or loss of power while using the equipment.

Exposure To Moisture And Wet Conditions

Moisture is a common cause of coil damage. When moisture penetrates the coil, it can cause short-circuiting or corrosion, which can lead to the malfunctioning of the equipment. If you work in wet or damp conditions, you should take care to keep the coil dry or use waterproof covers to protect it from moisture damage.

Improper Installation Or Wiring

Improper installation or wiring can also lead to bad coil performance. If the coil is not installed correctly or if the wiring is not properly connected, the engine may not function properly. It’s important to follow the manufacturer’s instructions for installation and wiring when replacing the coil to ensure it works correctly.

Any loose connection or incorrect wiring can lead to engine problems.

Damage From Foreign Objects Or Debris

Damage from foreign objects or debris can be a cause of bad coils. When debris, such as small rocks or tree branches, are sucked into the engine, they can damage the coil’s wiring or cause it to short circuit. It’s important to keep the engine area clear of any debris that may cause damage.

Overheating Due To Overuse

Overheating is another cause of bad coil performance. If the engine is overused or run at high speeds without enough breaks, it can cause the coil to overheat and fail. It’s important to take breaks during use and to regularly maintain the engine to prevent overheating.

A bad coil in a stihl engine can cause a lot of issues and should be addressed immediately. Age and wear and tear, exposure to moisture and wet conditions, improper installation or wiring, foreign object damage, and overheating due to overuse are among the main causes of bad coils.

Regular maintenance and attention to these potential issues can help keep your stihl engine running smoothly.

Troubleshooting A Bad Coil In A Stihl Engine

Stihl chainsaws are known for their high-quality performance and durability. However, even with the best maintenance practices, your stihl engine may develop issues over time due to prolonged usage. One of the most common issues is a bad coil; if you suspect that your stihl engine has a bad coil, you’ll notice several symptoms, including difficulty in starting the engine, misfiring, low power output, and engine stalling.

In this blog post, we’re going to focus on troubleshooting a bad coil in a stihl engine.

Step-By-Step Guide To Diagnosing A Bad Coil

Diagnosing a bad coil is usually not difficult, but you need to have some basic knowledge of small engines and their components. Here is a step-by-step guide to diagnosing a bad coil in a stihl engine:

- Remove the engine cover and the spark plug from the engine.

- Check for any damage to the spark plug, such as cracks or other defects. If the spark plug is damaged, replace it with a new one.

- Connect a spark tester to the spark plug wire, and then ground the tester to the engine block.

- Pull the starter cord a few times and observe the spark tester. If you don’t see any spark, that’s an indication of a bad coil.

- Test the ignition coil’s primary and secondary circuits using a multimeter. If the test results show that the resistance of the circuits is out of specifications, then you need to replace the coil.

Tools And Equipment Needed For The Process

To troubleshoot a bad coil, you’ll need the following tools and equipment:

- A spark plug wrench

- A spark tester

- A multimeter

Common Mistakes To Avoid When Troubleshooting

Avoid these common mistakes when troubleshooting a bad coil:

- Not replacing a damaged spark plug before testing the ignition coil, as this can lead to inaccurate diagnoses

- Connecting the spark tester to the spark plug wire instead of its output, which can lead to false negative readings

Tips For Easy Coil Replacement

If your tests confirm that the ignition coil is indeed faulty, you’ll need to replace it to restore your stihl engine’s normal operations. Here are some tips for an easy coil replacement process:

- Use genuine stihl replacement parts to ensure compatibility and reliability

- Follow the engine’s user manual to ensure you replace the coil correctly

- Consider replacing other critical engine components such as the fuel filter and spark plug for improved performance

When To Seek Professional Help

If you’re not comfortable troubleshooting a bad coil or are unsure of the proper procedure to follow, it’s advisable to seek help from a professional stihl mechanic. They have the necessary expertise and tools to diagnose and repair your engine in the shortest possible time.

A bad coil is a prevalent issue in stihl engines, but troubleshooting is usually simple, mostly requiring only a few tools and basic knowledge. By following the steps and tips outlined above, you can quickly diagnose and replace a bad coil, restoring your stihl engine’s full performance.

Preventing Coil Issues In Stihl Engines

Stihl engines are known for their power and reliability. However, even the best engines can run into trouble if they are not properly maintained and used. Coil issues are quite common in stihl engines and can be frustrating to deal with.

In this section, we’ll discuss some best practices to prevent coil issues in your stihl engine.

Regular Maintenance And Inspections

Regular maintenance and inspections can go a long way in preventing coil issues in your stihl engine. Here are some key points to consider:

- Check the air filter frequently and clean or replace as needed.

- Change the fuel filter and spark plug regularly.

- Drain the fuel tank and replace with fresh fuel every season.

- Inspect the engine for any signs of wear and tear.

- Keep the engine clean and dry to prevent moisture buildup.

Best Practices For Engine Use And Storage

Proper engine use and storage are crucial to prevent coil issues in your stihl engine. Here are some tips to keep in mind:

- Always use the recommended fuel mixture and fuel-oil ratio.

- Never run the engine at full throttle for extended periods.

- Let the engine run for a few minutes before turning it off.

- Store the engine in a dry, cool place, away from direct sunlight and moisture.

- Use a dust cover to protect the engine when not in use.

Avoiding Common Mistakes That Lead To Coil Issues

Coil issues can also arise due to some common mistakes. Here are a few things to avoid:

- Using old or stale fuel.

- Running the engine with a dirty air filter.

- Ignoring strange sounds or vibrations from the engine.

- Overheating the engine by running it for extended periods.

- Overloading the engine beyond its capacity.

Common Myths About Coil Replacement And Maintenance

There are many myths surrounding coil replacement and maintenance. Here are some key facts to keep in mind:

- Coil replacement is not always the solution to coil issues.

- Cleaning and inspecting the coil can often resolve the issue.

- Using cheaper replacement parts can actually cause more harm than good.

- Replacing the coil without addressing the underlying issue can result in further damage to the engine.

- Regular maintenance can prevent the need for coil replacement altogether.

Tips For Finding Reliable Replacement Parts

Finding reliable replacement parts can be a challenge, but it is crucial to ensure that your engine runs at its best. Here are some tips to help you find the right parts:

- Look for oem (original equipment manufacturer) parts.

- Read reviews and check the reputation of the supplier.

- Don’t compromise on quality for price.

- Ask for recommendations from other stihl engine owners.

- Check the warranty and return policy before making a purchase.

By following these best practices, you can prevent coil issues in your stihl engine and ensure that it runs smoothly for years to come. Remember to maintain and inspect your engine regularly, use it and store it properly, avoid common mistakes, and find reliable replacement parts when needed.

Happy stihl engine ownership!

Frequently Asked Questions Of Stihl Bad Coil Symptoms

What Is A Bad Coil In A Stihl Chainsaw?

A bad coil in a stihl chainsaw is a faulty electrical component that affects the firing of the engine. It can cause the chainsaw to stop working or have intermittent issues in starting or running smoothly.

What Are The Symptoms Of A Bad Coil In A Stihl Chainsaw?

Some common symptoms of a bad coil in a stihl chainsaw include difficulty in starting the saw, rough idle, stalling, reduced power, and failure to start. These issues may worsen as the coil deteriorates over time.

How Do I Test If My Stihl’S Coil Is Bad?

To test if your stihl’s coil is bad, you will need a digital multimeter. First, remove the spark plug wire and insert a spark plug tester into it. Then, connect the multimeter to the coil’s positive and negative terminals. Check the resistance reading, which should be between 0.

2 and 2 ohms.

Can A Bad Coil Cause A Stihl Chainsaw To Run Lean?

Yes, a bad coil can cause a stihl chainsaw to run lean. If the coil is not producing enough current, the spark plug will not ignite the fuel correctly, leading to incomplete combustion. This can result in a lean running condition that can damage the saw’s engine.

How Often Should I Replace The Coil In My Stihl Chainsaw?

There is no fixed interval for replacing the coil in a stihl chainsaw. It depends on various factors such as usage, maintenance, and environmental conditions. However, if you are experiencing any symptoms of a bad coil, it is recommended to have it checked and replaced if necessary.

Conclusion

From the symptoms discussed, it is clear that a malfunctioning ignition coil can greatly impact the performance of a stihl machine. If left unchecked, it can lead to power loss, misfiring, and even engine damage. However, with the proper maintenance and prompt identification of symptoms, these issues can be easily avoided.

It is crucial to regularly inspect the ignition system and replace faulty coils immediately to prevent further damage. Whether you are a professional landscaper or simply use your stihl equipment for home improvement projects, understanding the role of the ignition coil and recognizing its symptoms is vital to keeping your machine running smoothly.

With this knowledge, you can ensure the longevity and efficiency of your stihl equipment, providing you with the high-quality performance you need for your work or projects.

Leave a Reply